Chain Sling

Features

-

KITO link chain grade 10 achieves the world's strongest level.

-

Wide range of variations allow selection of the optimum combination for any application.

-

High product quality realizes safe and highly efficient work.

-

Advanced chain manufacturing technologies realize outstanding ultimate elongation.

-

Achievement of outstanding economic efficiency due to the high wear resistance.

Product Specifications

KITO's Sling Chain is High Quality as same as Load Chain used with Hoits.

Advanced Chain Manufacturing Technologies Realize Outstanding Link Chains

KITO link chains have both a high breaking stress and toughness due to the advanced chain manufacturing technologies that are utilized. This is verified by the numerical value of 20% or more achieved for the ultimate elongation based on the JIS standards requirements.

[Bending Capacity]

Concerning the strength in the link bending directin, the use of advanced welding technologies gives the links sufficient absorbability as shown by the photograph (below) of the result of beding test, and no breakage or cracking occours. (However, this does not indicate that the product should be used until it reaches the condition shown in the photograph.)

Wide Range of Variations allow Selection of the Optimum Combination for Any Application

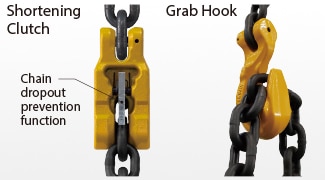

"Adjustment of Length" can be made, which is not Possible when Using Wires

When the load will not change for a certain period, use the shortening Clutch (VWW).

This has a chain dropout prevention function so that the chain will not drop out unexpectedly. Once the length has been set, work can be conducted repeatedly.

When the load changes frequently, use the Grab Hook (VFF, HGG).

Because attaching and detaching is easy, length adjustment can be swiftly conducted even if the load changes.

Allows Use Even in Severe Working Environments

Specification of products may differ depending on your location.

Please contact KITO and KITO's global partners for more information.