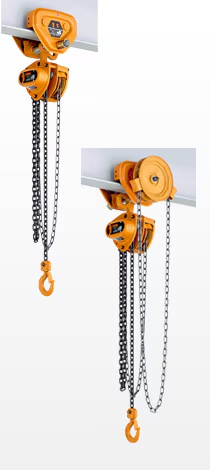

CB Series

Features

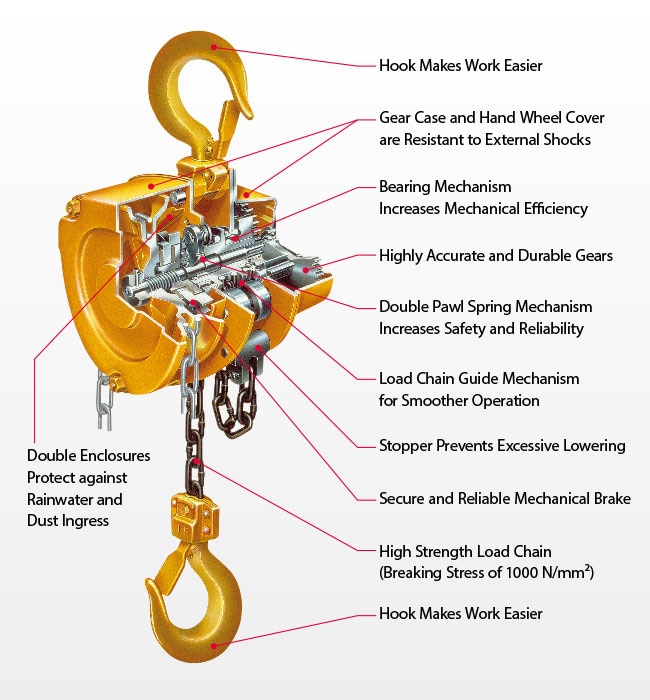

- Lighter, smaller, and more efficient, these hoists are invaluable for lifting applications.

- A high-class load chain with a breaking strength of 1000 N/㎟ (100 kgf/㎟) is key to reliable and safe operation.

- The dry-type braking mechanism provides excellent performance.

- Shock-resistant gear case and hand wheel cover.

- Double-pawl spring mechanism for extra reliability.

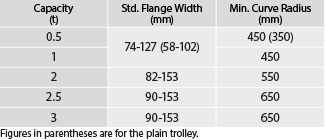

| apacity |

Geared Type : 0.5 to 20 t Plain Type : 0.5 to 5 t |

|---|---|

| Standard Lift | 2.5 m (0.5 to 1.5 t), 3.0 m (2 to 5 t), 3.5 m (7.5 to 20 t) |

| Operating Temperature |

CB : -40℃~+60℃ |

Product Specification

Standard Specification

Gear Case and Hand Wheel Cover are Resistant to External

Shocks

Double-pawl Spring Mechanism for Extra Reliability

Easy-to-use Hooks

Load Chain Guide Mechanism for Smoother Operation

Stopper Prevents Excessive Lowering

Double Enclosure to Seal Out Rainwater and Dust

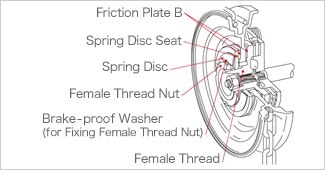

Secure and Reliable Mechanical Brake

Bearing Mechanism Increases Mechanical Efficiency

Highly Accurate and Durable Gears

High Strength Load Chain

Specification of products may differ depending on your location.

Please contact KITO and KITO's global partners for more information.

Specifications & Dimensions

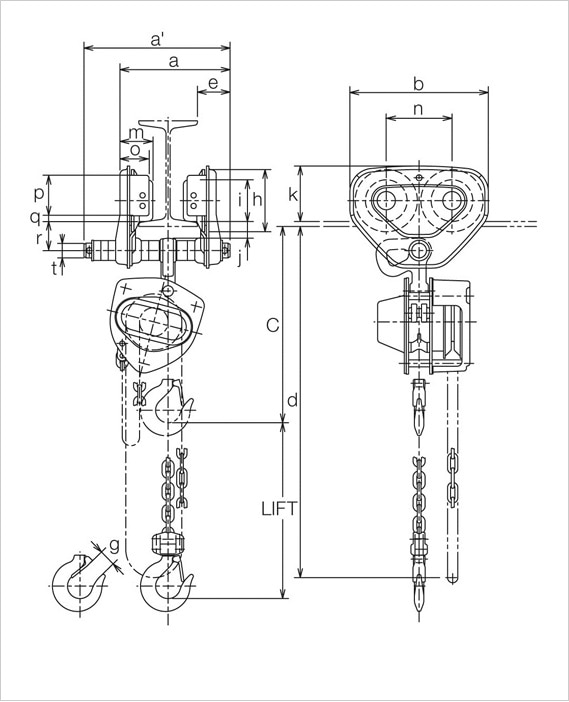

With Plain Trolley

Specifications

Product Catalog.

| Code | Capacity (t) |

Standard Lift (m) |

Flange Width Adjustability (mm) |

Mass (Net Weight) (kg) |

||

|---|---|---|---|---|---|---|

| Standard | Option | |||||

| W20* | W30* | |||||

| CBSP005 | 0.5 | 2.5 | 50-102 | 103-203 | 204-305 | 15 |

| CBSP010 | 1 | 58-127 | 128-203 | 19 | ||

| CBSP015 | 1.6 | 82-153 | - | 154-305 | 28 | |

| CBSP020 | 2 | 3 | 33 | |||

| CBSP030 | 3.2 | 44 | ||||

- CBSP means the CB series connected with the TS series plain trolley.

-

The data for the standard I-beam width and the minimum radius for a curve is the same data.

-

In case of only straight I-beam, 0.5 ton plain trolley can be used on 57 mm and less width beam and 1 ton plain trolley can be used on 73 mm and less width beam and 2.5 and 3 ton plain trolley can be used on 89 mm and less.

-

* W20 and W30 mean 203 and 305 mm flange width adjustability as option.

| Code | Headroom: C | a' | b | d |

|---|---|---|---|---|

| CBSP005 | 295 | 204 | 182 | 2500 |

| CBSP010 | 305 | 249 | 236 | |

| CBSP015 | 365 | 300 | 280 | |

| CBSP020 | 380 | 3000 | ||

| CBSP030 | 535 | 320 | 324 | 3100 |

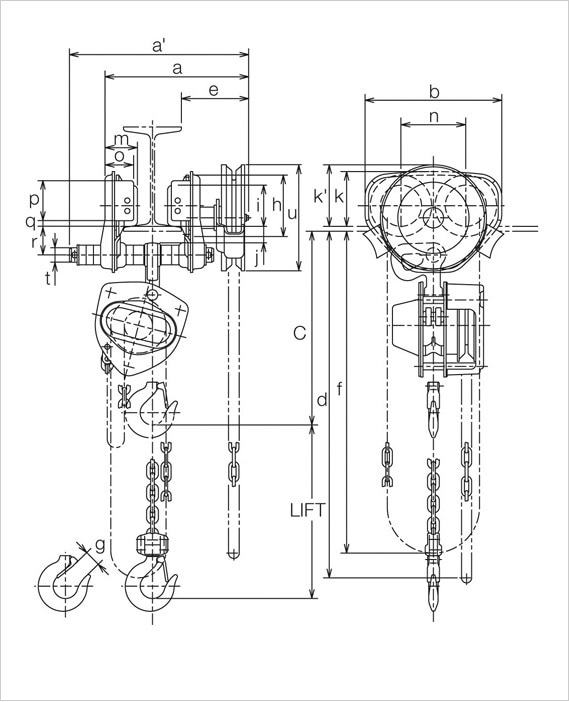

With Geared Trolley

Specifications

Product Catalog.

| Code | Capacity (t) |

Standard Lift (m) |

Flange Width Adjustability (mm) |

Mass (Net Weight) (kg) |

||

|---|---|---|---|---|---|---|

| Standard | Option | |||||

| W20* | W30* | |||||

| CBSG005 | 0.5 | 2.5 | 58-127 | 128-203 | 204-305 | 23 |

| CBSG0 | 1 | 24 | ||||

| CBSG015 | 1.5 | 82-153 | - | 154-305 |

32 |

|

| CBSG020 | 2 | 3 | 37 | |||

| CBSG030 | 3.2 | 48 | ||||

- CBSG means the CB series connected with the TS series geared trolley.

-

The data for the standard I-beam width and the minimum radius for a curve is the same data.

-

15 ton and over capacity trolleys have 8-wheel construction.

-

30 ton and over capacity versions are available by request.

-

In case of 7.5 ton and over capacity, trolley wheels for tapered flange are standard. Wheels for flat flanges are available as option. If you prefer wheels for flat flanges, please specify it in advance.

-

In case of only straight I-beam, 1 ton geared trolley can be used on 73 mm and less width beam and 2.5 and 3 ton geared trolley can be used on 89 mm and less.

-

* W20 and W30 mean 203 and 305 mm flange width adjustability as option.

| Code | Headroom: C | a' | b | d | f | |

|---|---|---|---|---|---|---|

| CBSG005 | 305 | 309 | 236 | 2500 | 2300 | |

| CBSG010 | ||||||

| CBSG015 | 365 | 385 | 280 | |||

| CBSG020 | 380 | 3000 | 2800 | |||

| CBSG030 | 535 | 398 | 324 | 3100 | ||

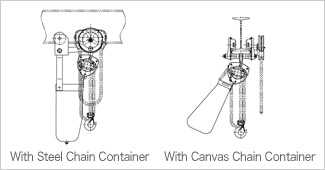

Option

Chain Container

Overload Protection Device (OLL)

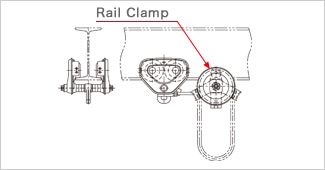

Trolleys for Curved Beams

Rail Clamp Device

Specification of products may differ depending on your location.

Please contact KITO and KITO's global partners for more information.